JVAF series vacuum annealing furnace

- Model

- JVAF433; JVAF644; JVAF755; JVAF966;JVAF1288;

Item specifics

- Max.temperature:

- 950℃ or 1350℃

- Pressure rising rate:

- 0.65Pa/h

- Air cooling pressure:

- 2Bar

- Ulitmater vacuum :

- 4*10-1Pa or 8*10-4Pa

- Temperature uniformity:

- ±5℃

- Heating element:

- Refractory steel or Molybdenum

- Size:

- Customized according to customer needs

Review

Description

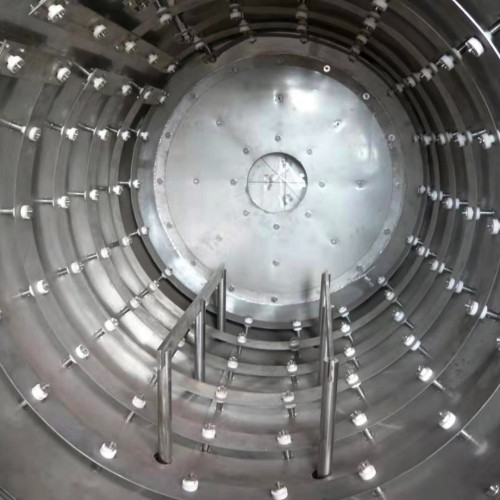

Product features

vacuum annealing furnace can ebe used for tools steel, moudl steel, high speed steel, stainless steel, Titanium alloy etc, we can supply with different configuration for different parts, it's going without oxidation, low distion, to reduce the engery consumption, we make with special heating chamber, it have good temperature uniformity and easy to operate.

1、Compact structure, highly-automatized operation,green and energy saving.

2、Equipped with magnesium collector to prevent the magesium powder to pollute diffusion pump.

3、Running safety and reliable , the control system can realize self-diagnosis,audible and visual alarm,interlock protection.

Configuration option

1、High vacuum for heating chamber

2、Air filter to clean exhaust air

Customized furnace still avaiable according to different requirement.

Product specification

|

Type

|

Hot zone (L*W*H,mm)

|

Loading capacity(Kg)

|

|

JVAF433 | 450*300*300 | 100 | |

|

JVAF644

|

600*400*400

|

200

|

|

|

JVAF755

|

700*500*500

|

300

|

|

|

JVAF966

|

900*600*600

|

500

|

|

JVAF1288 | 1200*800*800 | 1000 | |

JVAF1299 | 1200*900*900 | 1200 | |

JVAF1511 | 1500*1000*1000 | 1500 | |

JVAF202015 | 2000*2000*1500 | 3000 | |

JVAF551313 | 5500*1300*1300 | 7000 | |

JVAF1101515 | 11000*1500*1500 | 12000 | |

We can supply the vacuum furnace's maintenance service for different brands ,including routine maintenance,overhauling.

We also supplying of spare parts(graphite parts,molybdenum parts,ceramic parts,seal parts, thermocouples,elctronic instrument);Installation and commissioning;Maintenance and routine check;Training on operation and maintenance;Processing support.